Description

Tru Design marine fittings are precision moulded from a glass reinforced Nylon composite material which provides both maximum strength and durability.

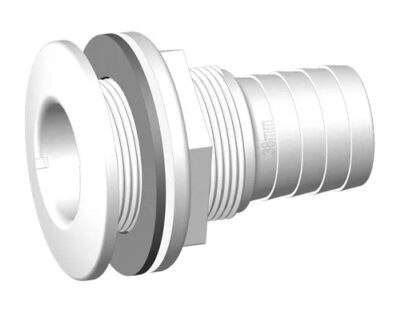

Designed and made in New Zealand, the Skin Fitting body and nut are moulded from a glass-reinforced nylon composite.

High strength, high-modulus glass fibres provide dramatic strength, stiffness, toughness and dimensional stability. These properties allow a significant weight reduction over metallic fittings.

TruDesign Skin Fittings eliminate the corrosion and electrical bonding problems associated with metallic fittings giving peace of mind with respect to the safety of your vessel.

They are compatible with all hull types and can be used on aluminium, steel, wood, composite & GRP hulls. The countersunk style head gives a streamlined look and reduces drag and the possibility of snagging. They can also be used as cockpit/tank drains.

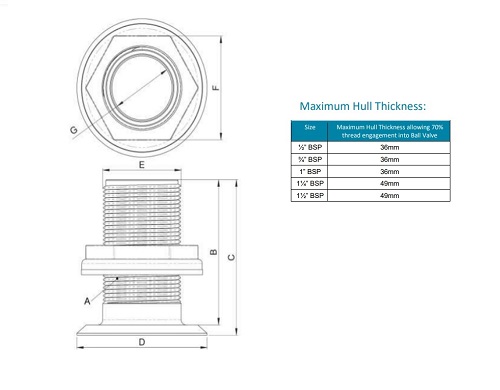

When used in below waterline applications, a Ball Valve should be directly connected for safety and compliance to relevant marine standards.

TruDesign range of Skin Fittings are certified by the International Marine Certification Institute (IMCI) and Bureau VERITAS to ISO 9093-2.

They also comply with ABYC H-27 500Lb standard when used in conjunction with the TruDesign ABYC collar.

FEATURES

-

- Manufactured from a glass-reinforced nylon composite – High strength and light weight

- Compatible with most hull types – Can be used on wood or GRP hulls

- Immune to corrosion and electrolysis – Long life with no concerns over decreased performance due to corrosion

- Chemical resistant – Impervious to diesel, petrol and antifouling paints

- UV resistant – Will not degrade or discolour with ultraviolet light from the sun

- High quality surface finish – Will not discolour with green film as similar bronze fittings do

- Paintable – Can be painted with all types of antifouling